Sawing is simply defined as a process of cutting any material but mostly woods and metal. Turning out attention to wood, hand or panel saws are used to cut pieces of wood into desired shapes for use mostly in small scale projects. Saw mills are charged with the responsibility of converting logs into wood and are more efficient for large scale projects that have increased work intensity.

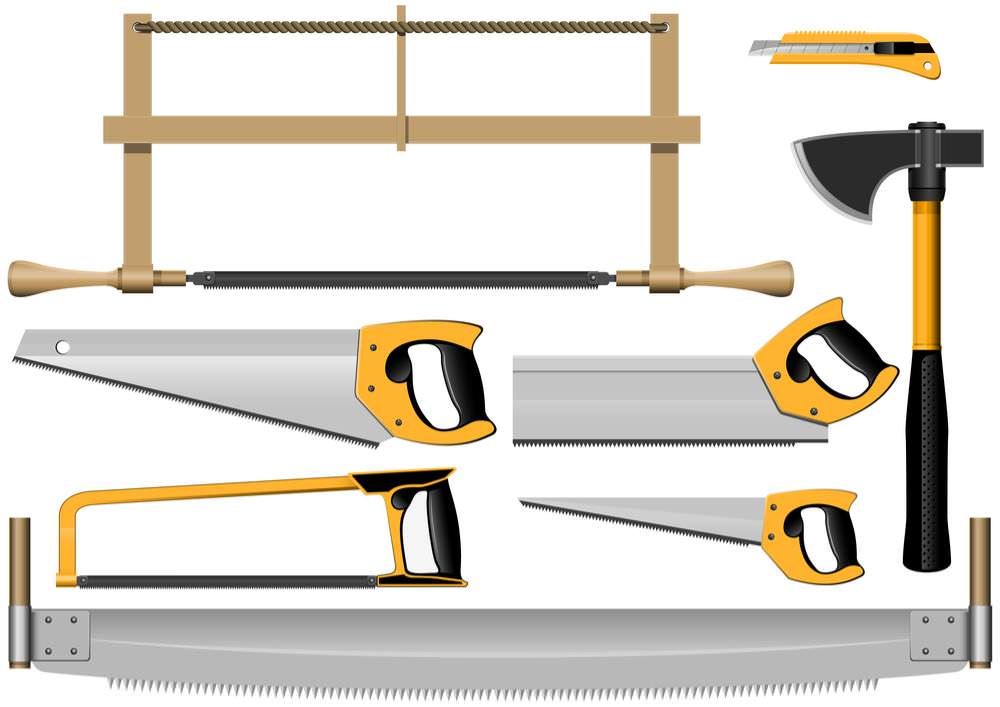

Types of hand saws

Hand saws are not only differentiated by the appearance which defines the purpose, but also by the shape of their teeth.

There are variations of hand saws that are suitable for different purposes:

Rip saw

It has huge teeth that have quite some spacing between them reducing their number to five for every inch. The huge teeth means that they are reduced in number for the entire saw thus making it cut a ‘larger length’ for every movement. It cuts along the fiber and the fiber patterns of the wood.

Crosscut saw

Its features and use directly contradict those of the rip saw. It has smaller teeth with more teeth per inch and hence best suited to cut against the fiber patterns of the wood. The teeth arrangement helps the saw remain intact for the cutting process.

Panel saw

It is related to the crosscut saw but with teeth that are closer together. It is best used in the cutting of plywood because it is ‘fragile’ as compared to other types of wood. Plywood is not as strong as normal planks of wood thus it is easily damaged during the hand sawing process. Care, therefore, needs to be taken when handling the wood and panel saw does just that.

Frame saw

It is more of a hybrid saw as it contains a metal frame for personalized changing of the teeth to serve different purposes thus combining the functions of the panel, crosscut and rip saws. It has a good handle for better holding when working with it.

Back saw

It also has small teeth that are closely placed together for excellent and more accurate cuts. Precision is improved with the thick bond that is located along its top thus it cannot curve when it is being used. It is, therefore, a suitable choice for areas that need accurate cuttings like wood joints. It is similar to the Japanese saw except this saw stroke backward instead of to the front.

Coping saw

It is characterized by a thin strip for the blade and superb teeth. The blade is embedded on a frame that is made of metal. The thin stripped blade means that it is easy to curve the saw for curved cuttings. Even with its purpose being similar to that of the scroll saw, their manufacturing designs are different.

Hack saw

It is majorly used with metal work rather than woodwork. It gums up on softer metals and hence cares is to be taken more so when it is used on aluminum material.

Other types of saws are not so common to find. They are mostly used in industrial setups and that is why they are not discussed. These types of saws include: circular saw (sidewinder and worm drive), table saw, oscillating saw, miter saw, band saw and jig saw.

Hand sawing tips

There are a number of tips that could make hand sawing more efficient and fulfilling process:

Cutline

This is mostly done with a pencil or a pen. A pencil is more reliable as changes and adjustments can easily be made. The cutline helps the person sawing in the sawing process thus mistakes are not made leading to wastage of material.

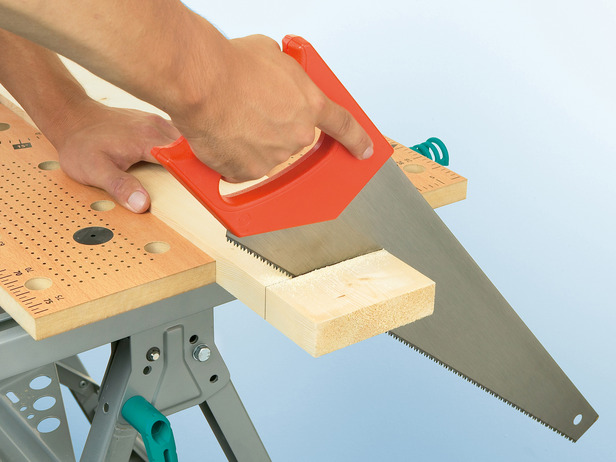

Starting cut

This is where the sawing process begins. Good practice involves using the thumb of the hand that is free to help direct the saw in making the initial cut.

Sawing angle

This is important as it defines the shape of the cut-out. There are different angles depending on the needs of the person sawing and hence the correct angle is determined by the correct positioning of the person sawing. It is good to apply some pressure on the wood like having it beneath the sawyer’s knee to avoid unnecessary movement that would lead to wastage of material.

Holding the saw

The saw should be held as close enough to the sawyer’s elbow as possible with the index finger aligned with the handle for a firmer grip of the saw. Long strokes should be made with deeper cuts. Stroking should not be parallel to the wood as this make stroking difficult. It should be done in the best slanting angle to the wood that can be achieved by the sawyer.

There are a number things to consider when buying a hand saw: teeth size and spacing, blade, ability to flex of the saw, the crown of the blade, the balance, the cost, and the purpose.