Concrete cutting is a messy business, literally. Concrete dust can take over if you are not careful. Concrete dust is very harmful to the body and can cause irreversible damage to your lungs.

It can also cause severe damage to your eyes if you do not wear the appropriate eye protection. This and more are the reasons why wet cutting is the best way to cut concrete.

It causes less damage to the concrete saw blade, produces less dust and is much safer for the saw operator and people within the vicinity.

There are several reasons why it is crucial to have a steady supply of water when cutting concrete. Here is our list.

1). Dust Control

Water keeps the dust from becoming airborne and keeps it from getting inhaled or getting into your eyes. This will save you and the people around you immense health risks. Wet sawing concrete is the safest way to cut concrete.

However, you will need a steady supply of water through a water hose or spray jets to ensure that the disk blade is constantly sprayed with water so the dust particles don’t become and airborne.

2). Heath And Safety Reasons

Having enough water supply while cutting concrete keeps the concrete saw operator and the workers around him safe from inhaling crystalline silica which can cause severe and irreversible damage to the lungs.

Spraying water on the concrete blade while cutting also keeps dust particles from entering the eyes causing severe eye damage.

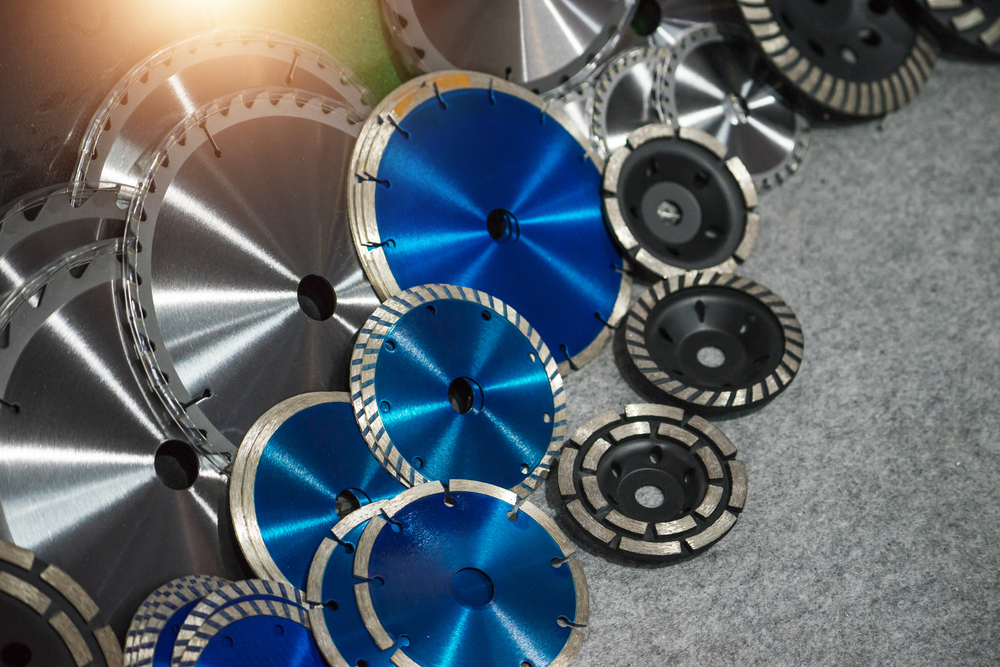

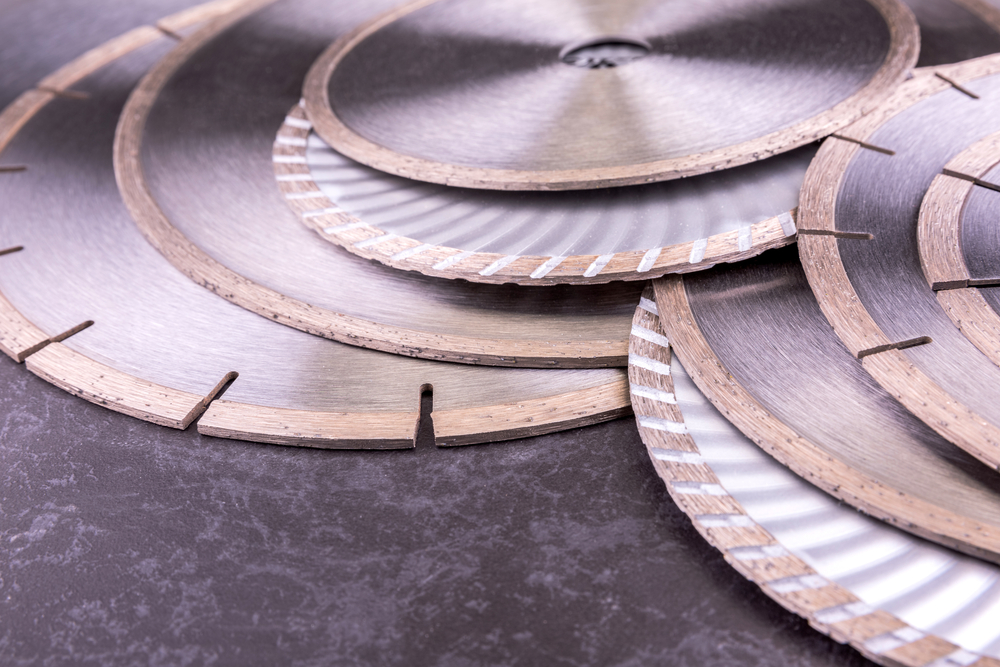

3). Keeping The Concrete Saw Blade Cool

Cutting through concrete is tough for the saw blades. Concrete is a hard and sturdy material. Cutting through concrete takes its toll on concrete blades. It can cause overheating which can cause the blades to crack or break.

Keeping the blades cool with the constant spraying of water while it cuts through concrete will minimise the effect of wear and tear and will significantly improve or prolong the lifespan of the blade and the concrete saw in general.

4). Environmental And Legal Guidelines

Concrete cutting in enclosed areas must only be done by wet sawing. Dry sawing concrete in this area can cause suffocation from the dust, lung damage, and many other fatal effects.

5). Reduced Noise Pollution

Wet sawing produces less noise from the concrete saw because the water keeps it relatively quiet.

This is important especially if you are working in enclosed spaces or buildings where there are other businesses and people who could be inconvenienced by the noise.

6). Preventing Flying Debris

When cutting concrete, small and sometimes large particles of concrete can fly through the air.

With a steady jet of water being sprayed on the blade, the water will ensure that any concrete that breaks off while cutting goes straight to the ground away from you and the people you work with.

7). Keeps The Space Clean Before, During And After Cutting

A steady supply of water while cutting helps keep the floor and work area clean and safe for everyone.

The water can be used to clean up before you start sawing the concrete, during, and especially after the work is done.

Important Reminders:

- Always check if the hoses are connected securely. Check for cracks, breaks or cuts.

- Adjust the nozzles so that the water goes directly onto the blade generously and wets the cutting area as well.

- Always inspect the concrete saw blade before using. Make sure it is in good condition and is maintained regularly.

- Always wear your Personal Protective Equipment or PPE from head to toe. Safety first!

Cutting concrete is not a job that should be done yourself if you do not have the experience, the skill, or the training to do it.

Handling concrete saws is challenging and pose so many health risks like losing a limb or worse still, fatally harming yourself.

For all concrete cutting needs, be it commercial or residential, call us at MEGASAW. We have over 20 years of experience providing quality concrete services in Melbourne. Our experience is your guarantee!

Please call us today on 1300 920 419 or contact us through our website.