Silicosis is a debilitating lung disease caused by inhaling silica dust, a common hazard in various industries, including construction. When silica-containing materials like concrete are cut, drilled, or ground, they release tiny particles of silica dust into the air, which, when inhaled, can lead to silicosis.

This article aims to explore the link between concrete cutting and silicosis, shedding light on the risks involved and the preventive measures necessary to protect workers’ health.

1. Introduction to Silicosis

Silicosis is a chronic and progressive lung disease caused by inhaling crystalline silica dust. This dust is generated during activities such as cutting, drilling, grinding, or crushing materials like concrete, stone, brick, and sandstone.

Over time, exposure to silica dust can lead to lung inflammation and scarring, impairing respiratory function and potentially causing disability or death.

2. Understanding Silica Dust

What is Silica?

Silica, or silicon dioxide, is a naturally occurring mineral found in rocks, sand, and soil. It’s a major component of many construction materials, including concrete, bricks, tiles, and countertops. Crystalline silica, the form of silica most commonly associated with silicosis, is abundant in these materials.

How Silica Dust is Generated

During the concrete cutting process, the friction and pressure applied by cutting tools like saws and drills generate silica dust as the silica-containing materials are broken down. This dust becomes airborne and can be inhaled by workers. Additionally, activities like jackhammering, sandblasting, and mixing concrete also produce silica dust.

Health Risks Associated with Silica Dust Exposure

Exposure to silica dust can cause a range of respiratory problems, with silicosis being the most severe. Other health risks include lung cancer, chronic obstructive pulmonary disease (COPD), and kidney disease. The severity of health effects depends on factors such as the duration and intensity of exposure, as well as individual susceptibility.

3. The Concrete Cutting Process

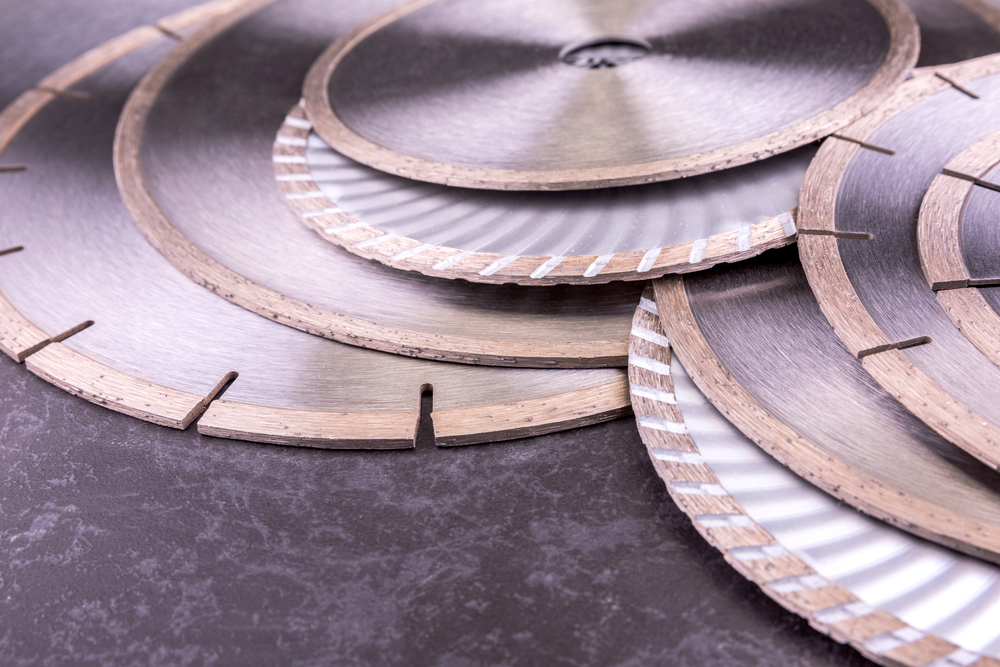

Methods and Tools Used

Concrete cutting involves various methods, each requiring specialised tools like diamond blades and drills. Sawing, drilling, and grinding are common techniques used to create openings in concrete structures for doors, windows, utility installations, and other purposes. While these methods are essential for construction projects, they also pose risks of silica dust exposure.

Generation of Silica Dust During Cutting

As the cutting tools come into contact with the concrete surface, they create friction and generate fine particles of silica dust. Without proper control measures, this dust can become airborne and spread throughout the work area, posing a health hazard to workers.

4. Silicosis: A Progressive Lung Disease

Symptoms and Diagnosis

Silicosis typically develops gradually over time, with symptoms including cough, shortness of breath, chest pain, and fatigue. Diagnosis often involves a combination of medical history, physical examination, and imaging tests such as chest X-rays and CT scans. Early detection and diagnosis are crucial for preventing further lung damage and managing the disease effectively.

Different Types of Silicosis

There are three main types of silicosis: chronic, accelerated, and acute. Chronic silicosis is the most common form and develops after long-term exposure to lower levels of silica dust. Accelerated silicosis occurs after more intense exposure over a shorter period, while acute silicosis is a rapidly progressing form caused by very high levels of silica dust exposure.

5. The Link Between Concrete Cutting and Silicosis

How Concrete Cutting Contributes to Silica Dust Exposure

Concrete cutting is a major source of silica dust exposure in the construction industry. The cutting process releases silica dust into the air, which can be inhaled by workers nearby. Without proper control measures, this dust can accumulate in the lungs over time, leading to silicosis and other respiratory diseases.

Research and Studies on Silicosis Among Concrete Workers

Numerous studies have documented the prevalence of silicosis among workers in the concrete cutting and construction industries. These studies highlight the need for stricter safety regulations and better enforcement of existing standards to protect workers from silica dust exposure.

6. Occupational Safety Regulations

Regulatory Standards for Silica Dust Exposure

Government agencies such as the Occupational Safety and Health Administration (OSHA) have established permissible exposure limits (PELs) for silica dust in the workplace. These standards set the maximum allowable concentration of silica dust that workers can be exposed to over an eight-hour period.

Compliance Requirements for Employers and Workers

Employers are responsible for ensuring that their workers are not exposed to silica dust levels above the permissible limits. This may involve implementing engineering controls, providing personal protective equipment (PPE), and conducting regular monitoring of silica dust levels in the workplace. Workers, on the other hand, must follow safety protocols and use PPE as required to minimise their exposure to silica dust.

7. Preventative Measures

Engineering Controls to Minimise Dust Generation

One of the most effective ways to reduce silica dust exposure is to implement engineering controls such as wet cutting methods, local exhaust ventilation systems, and dust suppression techniques. Wet cutting involves using water to keep dust levels low during cutting operations, while ventilation systems capture and remove dust at the source.

Personal Protective Equipment (PPE) for Workers

In addition to engineering controls, workers should wear appropriate PPE to protect themselves from silica dust exposure. This may include respirators with high-efficiency particulate air (HEPA) filters, goggles or safety glasses, gloves, and protective clothing.

Proper Ventilation in Work Areas

Proper ventilation is essential for maintaining good air quality in work areas where concrete cutting is performed. Adequate ventilation helps to reduce the concentration of silica dust in the air and minimise the risk of exposure to workers.

8. Health Effects of Silicosis

Impact on Respiratory Function

Silicosis causes inflammation and scarring of the lung tissue, leading to progressive respiratory impairment. As the disease advances, individuals may experience difficulty breathing, chest pain, and coughing, which can significantly impact their quality of life.

Long-term Consequences and Complications

In addition to respiratory symptoms, silicosis can lead to long-term health complications such as respiratory failure, pulmonary hypertension, and an increased risk of tuberculosis. These complications can significantly reduce life expectancy and quality of life for affected individuals.

9. Recognising and Managing Silicosis Risk

Training and Education for Workers

Raising awareness among workers about the risks of silica dust exposure and the importance of safety measures is crucial for preventing silicosis. Workers should receive comprehensive training on hazard recognition, safe work practices, and the proper use of PPE.

Regular Health Monitoring and Screening

Employers should implement regular health monitoring and screening programs to detect early signs of silicosis and other respiratory diseases among their workers. This may involve conducting pulmonary function tests, chest X-rays, and other diagnostic tests to assess lung health and detect any abnormalities.

Final Thoughts

Silicosis is a preventable disease, and minimising exposure to silica dust is key to preventing its onset. By raising awareness about the risks of silica dust exposure and implementing effective preventive measures, employers can protect the health and safety of their workers in the concrete cutting and construction industries.

Ensuring worker safety should be a top priority for employers in the concrete cutting industry. By adhering to regulatory standards, providing adequate training and PPE, and promoting a culture of safety in the workplace, employers can create a safer and healthier environment for their workers, reducing the risk of silicosis and other occupational diseases.

At Megasaw, we offer a range of electric and gas concrete cutting machines to meet the diverse needs of our clients. Our team of experts can help you choose the best option for your project and provide professional and efficient cutting services.

If you are looking for a specialist concrete cutting company who uses only the best practices to get the job done right, then please call us at Megasaw on 1300 920 419 or contact us through our website.