Concrete cracks are fairly common. In fact, sometimes they are even considered inevitable occurrences. Concrete cracks are so common that they have actually been classified into 6 common types. If you would like to learn more about this, then please keep on reading below!

1). Plastic Shrinkage Concrete Cracks

The plastic state of concrete is the state before it hardens. In this state, it is still full of water. However, when the water evaporates, it can leave behind large voids between the solid particles. These empty spaces are weak spots of concrete that are prone to cracking.

Plastic shrinkage cracks can happen on concrete slabs or walls, but they often happen at the reentrant corners, or corners that point into the slab. They also occur in the middle of circular objects such as pipes, plumbing fixtures, drains or manholes.

Plastic shrinkage cracks are also very narrow and barely visible. However, the cracks do not only exist on the surface. Rather, they can extend throughout the thickness of the concrete slab.

Control joints may be introduced into the concrete slab in order to prevent plastic shrinkage concrete cracks.

2). Expansion Concrete Cracks

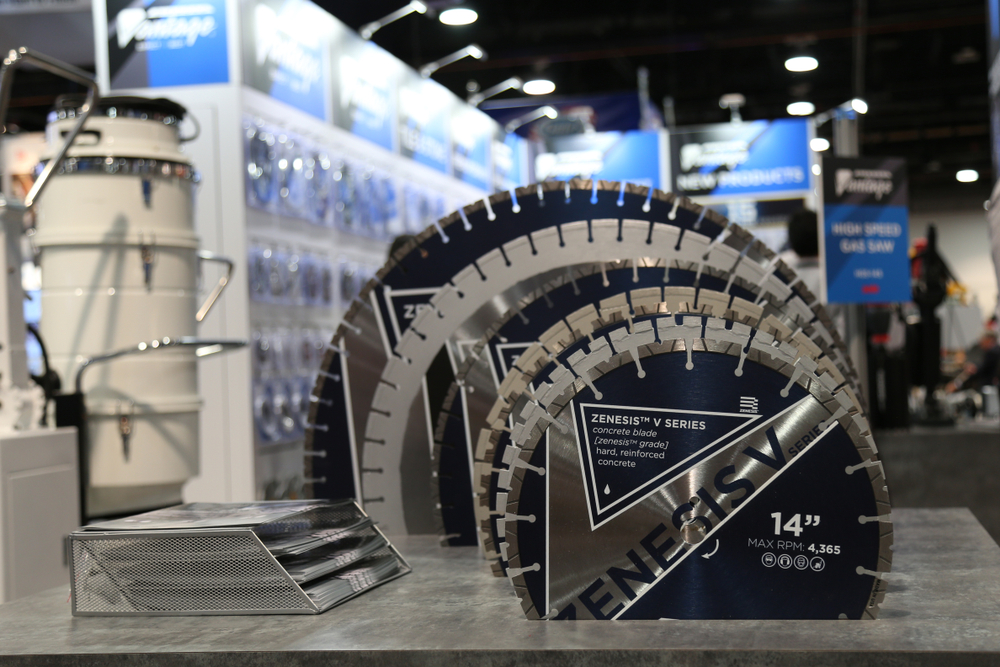

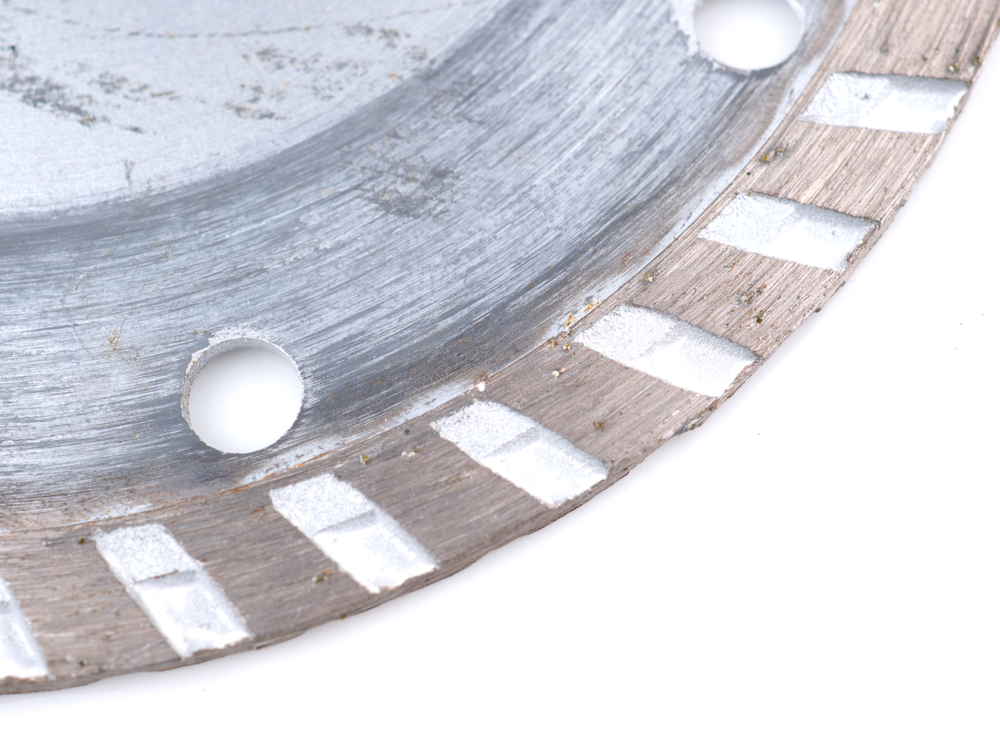

Expansion concrete cracks are caused by heat. When heat expands the concrete, it can push outwards against anything, and the expanding force can lead to concrete cracks. This is where concrete cutting comes into the equation.

Expansion joints are commonly cut into the concrete as a point of separation between static surfaces. They primarily act as shock absorbers to help relieve the stress that the expansion force may exert on the concrete. This can ultimately help prevent cracking.

3). Heaving Concrete Cracks

Heaving concrete cracks occurs when the ground freezes and lifts up a couple of inches before thawing and settling down. The ground movement caused by freezing and thawing can result in concrete cracks. If the slab cannot move with the ground, it will crack.

Tree roots also exhibit the same effect on concrete. If a tree root is located in close proximity to a concrete slab, it can lift it and cause it to crack. Hence, this is something to consider before laying out concrete slabs.

4). Settling Concrete Cracks

Settling concrete cracks occurs when the ground settles beneath a concrete slab. This happens when a void is created in the ground underneath the concrete surface. This is more prone to occur if the soil underneath is not compact enough or if tree roots decompose.

All of these things can lead to concrete cracks, especially if the base or ground where the concrete slab will be placed is unstable, not compacted and unprepared.

5). Cracks Caused By Overloading The Slab

Even though concrete is a strong material, it too has its own limits. Concrete cracks can also occur if the concrete slab is overloaded.

Different concrete mixes specify that they have different strengths. While overloading concrete slabs is not super common, what is more important is the issue of excess overload on the ground beneath the slab.

Excessive weight on the slab, especially after heavy rain, can press down on the slab and cause it to crack. This is common for homeowners that place large recreational vehicles or a dumpster on their driveway.

6). Cracks Caused By Premature Drying

There are actually two types of cracks that are caused by premature drying.

The first type of crack is called crazing cracks. They are fine surface cracks that sort of looks like spider webs or cracked glass. Crazing cracks occur if the surface of the concrete slab loses moisture too rapidly. They are not usually a concern for structural issues, though.

The other type of crack is called a crusting crack. They often occur during the concrete stamping process where textures or patterns are added to concrete surfaces. If the top of the slab dries quicker than the bottom on, say, a windy day, then this can cause crusting cracks.

Once the stamp is applied, it can pull apart the surface near the stamped areas and cause small cracks around the outside edges. Similar to crazing cracks, crusting cracks are not a point of structural concern.

Summary

While there are many types of different cracks in concrete, it may be hard to pinpoint exactly which type of concrete crack it is. It is important to consult with an experienced professional who will not only be able to identify what crack you are dealing with but to help suggest solutions by which these cracks can be remedied.

If you need concrete sawing performed safely and reliably, be it commercial or residential, please call us at MEGASAW.

We have over 20 years of experience providing quality concrete cutting services all over Melbourne. Our experience is your guarantee!

Please call us today on 1300 920 419 or leave an inquiry.