Concrete cutting is no easy task. There can be a lot of hazards associated with it if you don’t take the necessary precautionary steps. Therefore, before cutting concrete, it is important to be aware not only of what to do but also what not to do as well.

If you would like to learn more about the do’s and the dont’s of concrete cutting, feel free to continue reading our article below.

The Do’s Of Concrete Cutting

While there are some mistakes that you can potentially make during the concrete cutting process, there are also a few things you need to get right when cutting concrete. These include the following:

1). Do wear protective gear

Regardless of what type of construction job you are carrying out, it is always important to wear the right protective gear. Some of these items include protective glasses, rubber boots, masks or ventilators, long-sleeves and pants and of course, earplugs/earmuffs.

2). Do take it slow

Don’t rush a concrete cutting job. Using a concrete saw properly means slow, delicate work that can take hours to accomplish. For best results, it’s best to create several shallow passes when cutting concrete instead of making one deep cut on the first try. If you cut too deep and too fast, you can damage your concrete saw blade and cause your equipment to overheat.

3). Do create proper water flow

Most saws used to cut concrete are wet saws, which means they require a flow of water in order to create precise cuts and mitigate the amount of dust created during the cutting process. While a wet saw is the best saw to use when cutting concrete, it is critical that you have a good flow of water and everything is hooked up properly. Never use a dry saw blade with a wet saw machine.

The Dont’s Of Concrete Cutting

Before cutting concrete, it is important to know what not to do in order to avoid safety hazards and accidents. Here are a few things not to do when cutting concrete:

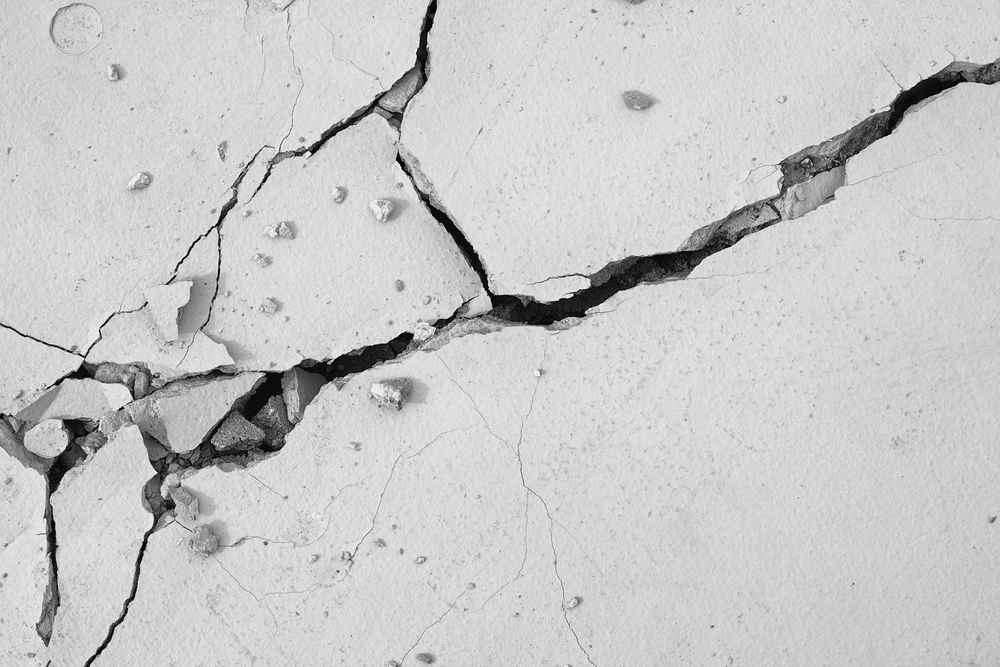

1). Don’t use damaged equipment

Using damaged equipment is incredibly dangerous and will pose severe safety hazards. Damaged blades will also not be able to create effective cuts. Before cutting, make sure to thoroughly inspect your blade and ensure it is not cracked or missing a tooth. Use a fresh and sharp blade if your current blade is damaged. Make sure to keep the blade guard down before cutting.

2). Don’t work in a poorly ventilated area

Working in a poorly ventilated area can be very toxic especially since most concrete saws that run on gasoline or diesel will create harmful fumes. Fumes and the combination of large amounts of dust will be very toxic if you are not working in an open space.

If you are carrying out a construction project that has been roofed and framed, make sure to wear a mask and have fans around to circulate fresh air and push away dust. For enclosed sites, try to open as many windows as you can and use the fans to keep airflow consistent.

3). Don’t work without a safe lifting method

Concrete cutters can be very heavy, so you will need to have a lifting and lowering method in order to protect your legs and lower back. If necessary, you can wear a back harness and brace to help keep you steady when you lift and cut concrete, most especially if you are cutting the side of a concrete wall.

Summary

In concrete cutting, there are a few must-do’s that you should perform in order to remain safe during the process: do wear protective gear, do take it slow, and do make sure you have good water flow. Meanwhile, there are certain mistakes that you must avoid in order to prevent safety risks and hazards: don’t use a damaged blade, don’t work in a poorly ventilated area, and don’t work without a safe lifting method.

If you need asphalt sawing performed safely and reliably, please call us at MEGASAW. We have over 20 years of experience providing quality concrete and asphalt cutting services all over Melbourne. Our experience is your guarantee!

Please call us today on 1300 920 419 or leave an inquiry.