Are you currently working in an industry that heavily utilises concrete? Whether for developments or manufacturing, concrete is a staple resource that is used in many different fields of business. Whenever there’s concrete involved, there is almost always a cutting service that is required. Concrete is a hard and durable material and needs professional assistance in order to cut. Getting high-quality concrete cutting is critical for business success, thus here’s a comprehensive guide on how you can choose the right cutting service

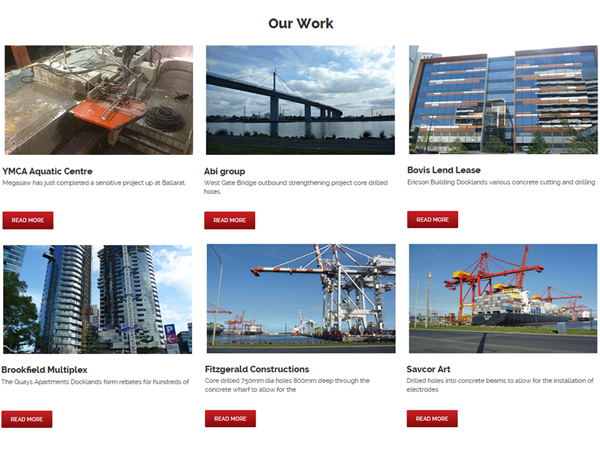

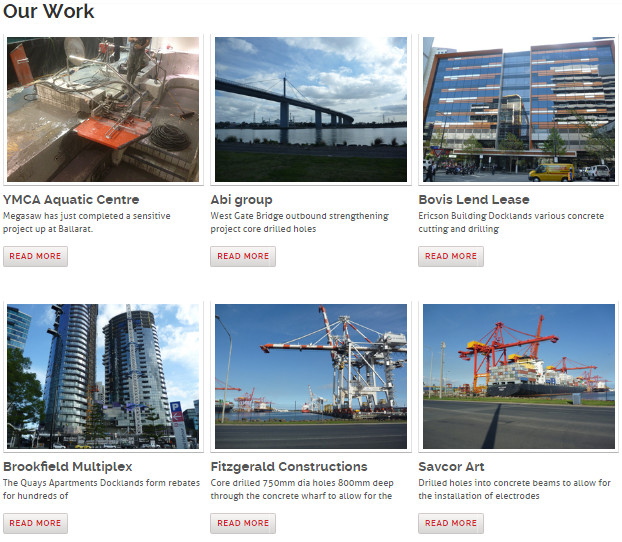

Great Portfolios Represent Great Experience

Did you know that many well-established firms that provide cutting services for concrete will have a portfolio that is available to be viewed by prospective clients? Portfolios include all of the past engagements that the business has worked on in the past. The great thing about portfolios is that they are a tremendously reliable measure of the past quality of work of a given concrete cutter.

When searching for the right service, looking through all of the various portfolios of concrete cutting services in the area is a great first step. By being able to gauge the types of projects a business has been assigned in the past, an idea of what kind of cutting services the company excels at can be ascertained. It’s worth noting that certain cutting services will be better at one type of cutting than another. It’s up to you to choose the right business which has a proven track record in the project you’re currently working on.

Safety Standards as an Indicator or Reliability

Have you considered the correlation between safety standards and quality of service? Many people that utilise the services of concrete cutters don’t realise that by looking at the safety protocols of a cutting firm, they can reliably judge the quality of service the firm can provide.

Many safety protocols are required to be followed to ensure the safe provision of cutting concrete. These include everything from conducting the cutting in an enclosed and safe area, all the way to having the cutters wear complete safety gear. There is plenty of information within the industry that goes into detail about all of the specifics concerning the safe cutting of concrete.

Services that don’t follow these protocols by taking safety shortcuts are significantly likely to provide a poor quality service. It is an unspoken rule throughout various development and manufacturing businesses that services which disregard the importance of safety are likely to ignore the quality of service that they provide. Considering that they are willing to take shortcuts with safety, it isn’t a long stretch for them to start taking shortcuts with how they carry out cutting services. Firms that are meticulous in ensuring the right safety of their employees are likely to be just as stringent in making sure that they can deliver a quality cutting procedure for their clients.

Quality of Equipment Determines Quality of Service

There is a common saying that a tradesperson is only as good as the tools that they use. This is definitely the case with concrete cutting. The quality of cutting equipment that is utilised will bear great significance in the precision of the concrete cutting that is carried out. Quality equipment dictates so many different variables from how quickly the concrete can be cut, to how precisely the cut can be made. For businesses that require highly specific measurements for concrete, it is essential that whichever company they choose uses the highest standard in equipment.

Most firms that provide a cutting service for concrete will advertise the types of equipment that they use. These firms understand that equipment is vitally important to their effectiveness in carrying out business. Hence, firms that are unwilling to showcase the various brands and models of tools that they use are likely trying to hide something. Firms which happily boast about how high quality their equipment is will probably have all the tools required to provide top-quality service.

The Importance of Insurance

When was the last time you checked if a service firm you utilised had been adequately insured? Many businesses just assume that the company that they have hired for manual services such as concrete cutting are insured. However, many firms are either inadequately insured or have no insurance at all. It’s essential for any manager or business owner to make the right inquiries to ensure that whoever they contract with has the right amount of insurance.

It’s important to dig deep regarding the insurance of a firm providing a cutting service. Quality firms will be able to quickly reassure clients about all of the various technicalities about their insurance policies and how they are qualified to provide their service. Firms that are not be trusted will be unwilling or uncooperative in assisting potential clients looking to find out more about their insurance policies. Insurance ensures that any service can be carried out safely and securely for both parties. When it comes to concrete cutting, it’s essential that all aspects of insurance are appropriately recognised and understood.