Concrete cutting has gone through several changes in the last few decades. From using the jackhammer to the use of heavy sawing machines, the evolution of the concrete cutting solutions has been amazing. These have helped different industries and been a part of many construction projects. Be it for creating a new entry to a building or paving a path for a better road, concrete cutting services have always been necessary. The construction industry has required these specialized services more than any other sector.

Let’s take a look at how these services have benefited various industries and different projects:

1) No sound or air pollution

Even a decade back, when the machines were not as developed as today, there was too much noise when the drills and saws cut through concrete. You could not be anywhere near the machines because of the searing noise. Everyone involved in the project would take a break when the saws were in full flow. In fact, most of the concrete cutting in the construction projects was done when the workers were away. And, let’s not even begin with the respirable dust that got emitted from those machines. However, with the modern machines, things have changed for the better.

The modern machines do not produce so much noise or dust. With minimal noise, it has become easier for construction projects to be completed quickly. Not only for construction projects, there are times when concrete cutting is required by homeowners. Neighbors would have been irritated with all the noise of the concrete machines but not anymore!

2) Precision and accuracy

This is another reason why road makers and construction companies require the services of a concrete cutting company. The construction industry needs accurate cutting for setting up doors and windows. This can only be done by experienced concrete cutters. They have gigantic sawing machines that are specially designed to cut down walls to make way for doors and windows. Diamond blades are used in the machines to cut through walls. There is no denying that these machines have been a boon to the construction companies. They can cut down the thickest of walls within the wink of an eye.

Before the walls are cut down, the expert will check the measurements where the cut has to be made. The diameter of the blade is set accordingly. After that, the machine is switched on the walls are cut. These machines can also cut walls according to specific designs. Sometimes, the rooms need special openings that are not used for doors and windows. These designs can also be cut by the concrete cutting machines.

3) Fast and efficient

Let’s face it; the days when the jackhammer and chisel were used, it was such a pain for the workers to work in the scorching heat and break concrete floors or walls. They would take hours to finish a particular job and that extended the project longer than usual. With the modern concrete cutting machines, things have become faster. The work of almost 3 workers can now be done by one single person. It has been possible because of the evolution of the machines. The machines used these days come with inbuilt water container so that the machines do not leave a lot of mess in the form of dust and dirt.

The chances of missing a deadline have gone down. Be it a big or small construction project, you can be assured that the quality of work will be maintained even when the work is being done faster than normal.

4) Efficient for working in smaller areas

One of the biggest advantages of opting for the services of concrete cutting is that they can work within a very small space. There have been cases when concrete walls have to be cut to get through to the plumbing system of a house. This requires the precision and accuracy of the cutter to work within a space that will not be more than a couple of feet. There are machines that can be used in such small spaces too. Handsaws that specialize in working in small areas are used in such projects.

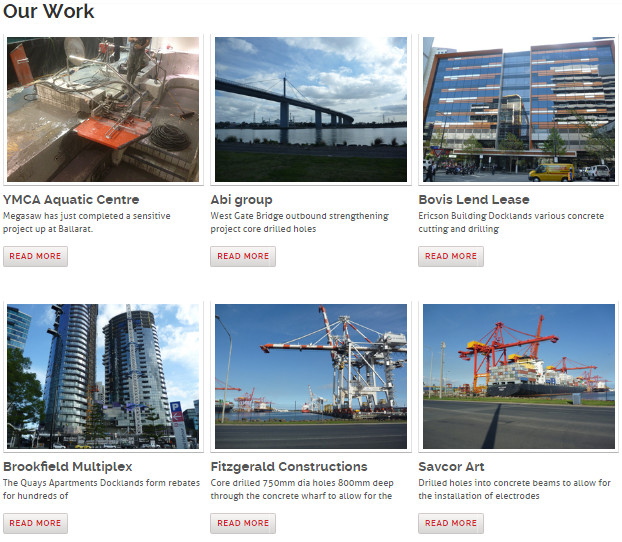

At MEGASAW, you can expect to get the best concrete cutting service that will give you your money’s worth. We have a dedicated team of cutters who can take up any challenge you throw at us. They have been a part of numerous projects for some of the most eminent companies. We have come up with a combination of techniques that have helped to cut through concrete easily. Apart from our quality service, we charge the least and you are free to compare the fees with other companies. Give us a call at 1300 920 419 to discuss your project and we assure you that you will be totally satisfied.